Fabric Banner Solutions: Professional Polyester Display Options for Trade Shows and Events

Professional fabric banner technology transforms business displays through advanced polyester materials and dye sublimation printing. These professional cloth banners deliver superior visual impact while maintaining portability and durability. Singapore businesses increasingly choose fabric banners over vinyl alternatives for premium indoor applications and sophisticated brand presentations in the competitive exhibition market.

Professional fabric banners utilize specialized polyester weaves ranging from lightweight 3.5oz materials to heavy-duty 9oz constructions. Moreover, the dye sublimation printing process creates vibrant, fade-resistant graphics that penetrate deep into fabric fibers. Consequently, these custom cloth banners maintain exceptional color quality through repeated use and professional cleaning cycles.

Understanding Fabric Banner Materials and Construction

Premium polyester fabric banners feature tightly woven synthetic fibers designed specifically for display applications. Furthermore, manufacturers engineer these materials to resist wrinkles, tears, and environmental damage while maintaining lightweight portability. Professional banner cloth material typically weighs between 3.5 ounces and 9 ounces per square yard.

Lightweight 3.5oz fabric provides excellent ink penetration and cost-effective solutions for short-term displays. Additionally, standard 6.8oz polyester offers balanced durability and print quality for most trade show applications. Heavy-duty 9oz fabric banners deliver maximum longevity and premium appearance for high-end corporate events and permanent installations.

The polyester construction enables machine washing capabilities while preserving graphic integrity. Similarly, these fabric display banners fold compactly for efficient transportation without permanent creasing. Professional cloth banner stands accommodate various fabric weights through adjustable tension systems and specialized mounting hardware.

Dye Sublimation Printing Process and Quality Benefits

Dye sublimation printing creates permanent color integration by converting solid dyes into gas through heat application. Subsequently, these gaseous dyes penetrate polyester fibers at the molecular level, creating scratch-resistant and washable graphics. This advanced printing technique produces continuous-tone images without visible dot patterns or pixelation.

Professional dye sublimation utilizes CMYO color sets (Cyan, Magenta, Yellow, Overcoating) rather than traditional CMYK printing. The overcoating layer provides UV protection and moisture resistance for extended display life. Consequently, fabric banner printing achieves photographic quality with exceptional color vibrancy and detail reproduction.

Temperature-controlled transfer processes operate at 400+ degrees Fahrenheit to ensure complete dye penetration. Moreover, pressure application during transfer creates uniform color distribution across large format displays. These technical specifications enable custom fabric banners to maintain consistent quality across production runs.

Fabric Banner vs Vinyl Banner Comparison

Fabric banners excel in indoor environments where sophisticated appearance matters most. Unlike vinyl alternatives, polyester fabric banners absorb light rather than reflecting it, eliminating glare during photography sessions. Additionally, fabric materials provide superior draping characteristics for curved surfaces and architectural installations.

Professional cloth banners offer significant weight advantages over comparable vinyl solutions. Transport costs decrease substantially since fabric banners fold compactly without damage risk. Furthermore, setup time reduces dramatically through easier handling and positioning capabilities during trade show installations.

Maintenance requirements differ significantly between material types. Fabric banners require gentle machine washing with mild detergents and air drying procedures. Conversely, vinyl banners need surface cleaning with damp cloths and careful rolling for storage without permanent creasing.

Trade Show and Exhibition Applications

Trade show fabric banners create professional booth environments that attract qualified prospects and enhance brand perception. Premium polyester materials photograph beautifully under exhibition lighting without unwanted reflections or color shifts. These fabric exhibition banners integrate seamlessly with existing display systems and portable banner stands.

Step and repeat banners utilize fabric construction for media walls and photography backdrops. The matte finish eliminates hot spots and provides consistent lighting across the entire display surface. Professional photographers prefer fabric backdrop banners for their superior color reproduction and wrinkle-resistant properties.

Tension fabric displays stretch seamlessly across curved frames without visible seams or distortion. These systems accommodate large graphics up to 50 feet wide without joining multiple panels. Consequently, fabric trade show displays deliver uninterrupted brand messaging across expansive booth spaces.

Corporate event planners select premium fabric banners for their sophisticated appearance and versatility. Whether suspended from ceiling structures or mounted on portable stands, these displays maintain professional aesthetics throughout extended event durations. Singapore's major exhibitions like FHA-Food & Beverage Asia, COMEX SHOW, and BUILDTECH ASIA showcase increasing adoption of fabric display solutions. Custom sizing options ensure perfect fit for any venue configuration at Singapore Expo or Marina Bay Sands convention facilities.

Professional Installation Hardware and Mounting Systems

Grommets vs Pole Pockets: Complete Comparison Guide

Professional fabric banner installations utilize two primary mounting systems, each offering distinct advantages for specific applications. Understanding these differences ensures optimal display performance and longevity. Meanwhile, proper hardware selection directly impacts installation time, appearance quality, and weather resistance capabilities.

Grommet finishing creates reinforced mounting points through stainless steel rings embedded along banner edges. These metal rings distribute tension evenly while preventing fabric tearing during wind exposure. Furthermore, grommets accommodate various hanging accessories including rope, bungee cords, zip ties, carabiners, and hanging clips for maximum installation flexibility.

Standard grommet spacing occurs every 12-18 inches for small banners, 18-24 inches for medium displays, and 2-3 feet for large installations. Additionally, corner grommets provide essential stability points regardless of banner size. Professional installations utilize ¼-inch grommet openings with external diameters of 0.75 inches for optimal hardware compatibility.

Pole pocket construction eliminates visible hardware through sewn sleeves along banner edges. These 3-inch diameter pockets accommodate standard 1-inch, 2-inch, or 4-inch diameter poles depending on application requirements. Moreover, pole pocket installations create smooth, wrinkle-free displays ideal for corporate environments and photography applications.

Professional Hanging Accessories and Hardware

Nylon rope provides versatile hanging solutions for both grommet and pole pocket installations. Weather-resistant properties ensure long-term outdoor performance while maintaining strength through repeated exposure cycles. Professional installations utilize marine-grade rope for enhanced durability in challenging environments.

Bungee cords offer dynamic tension management for outdoor fabric banners exposed to wind conditions. These elastic connectors absorb sudden force impacts while maintaining consistent banner positioning. Additionally, bungee cord installations enable easy removal for cleaning and maintenance procedures without permanent hardware modifications.

Carabiner clips create secure connections between grommets and mounting points through spring-loaded mechanisms. Stainless steel construction resists corrosion while providing reliable operation through thousands of engagement cycles. Furthermore, carabiner installations enable rapid banner changes without tools or specialized equipment.

Velcro adhesive strips provide removable mounting solutions for temporary installations and frequently changed displays. Professional-grade adhesive maintains bonding strength through extended use while enabling clean removal without surface damage. These systems work particularly well for indoor retail environments requiring regular graphic updates.

Advanced Installation Techniques for Maximum Impact

Tension fabric display systems stretch banners across aluminum frames for seamless, wrinkle-free presentations. These professional installations eliminate visible joints while accommodating graphics up to 50 feet wide without seams. Subsequently, tension systems create architectural integration opportunities for permanent brand installations.

Ceiling suspension installations maximize vertical space utilization in exhibition environments. Professional rigging hardware distributes weight safely while enabling adjustable height positioning. Moreover, overhead installations create dramatic visual impact without consuming valuable floor space in crowded venues.

Multi-banner arrays combine individual panels for large-scale visual displays. Professional alignment systems ensure perfect registration between adjacent banners while maintaining consistent tension across the entire installation. These configurations work exceptionally well for step-and-repeat photography walls and architectural branding applications.

Technical Specifications and Quality Standards

Fabric Weight Classifications and Performance Characteristics

Professional fabric banner materials range from lightweight 3.5oz economy options to heavy-duty 9oz premium constructions. Each weight classification serves specific applications while balancing cost effectiveness with performance requirements. Understanding these specifications enables optimal material selection for intended use environments and duration expectations.

Economy 3.5oz polyester provides cost-effective solutions for short-term indoor displays and budget-conscious applications. This lightweight material offers excellent ink penetration for vibrant graphics while maintaining foldability for efficient storage. However, transparency characteristics may allow light bleed-through, making it less suitable for backlit environments.

Standard 6.8oz polyester represents the industry benchmark for professional fabric banner applications. This balanced construction delivers optimal durability while maintaining lightweight portability characteristics. Additionally, reduced transparency prevents unwanted light transmission while preserving color saturation under various lighting conditions.

Premium 7.35oz and 9oz materials provide maximum durability for high-traffic environments and extended outdoor exposure. These heavy-duty constructions resist tearing, stretching, and environmental damage while maintaining dimensional stability through repeated setup cycles. Furthermore, enhanced opacity eliminates transparency concerns for critical brand presentations.

Advanced Printing Technologies and Color Management

Dye sublimation printing achieves photographic quality through 1200-1440 DPI resolution capabilities. Professional systems utilize CMYO color sets (Cyan, Magenta, Yellow, Overcoating) rather than traditional CMYK configurations. The overcoating layer provides UV protection and moisture resistance while enhancing color depth and vibrancy.

Heat transfer processes operate at precisely controlled temperatures between 380-420 degrees Fahrenheit. This thermal energy converts solid dyes into gaseous states, enabling deep penetration into polyester fiber structures. Subsequently, rapid cooling permanently locks color molecules within fabric matrices for scratch-resistant, washable graphics.

Color matching services ensure accurate brand representation through Pantone color system compatibility. Professional printing facilities maintain calibrated equipment and controlled lighting environments for consistent color reproduction across production runs. Moreover, advanced profiling systems compensate for material characteristics and environmental variables affecting final output.

Quality control procedures include 33-point inspection processes covering color accuracy, registration precision, and finishing quality. UV curing systems dry inks instantly while preventing color bleeding or smudging during production. These comprehensive quality measures ensure every fabric banner meets professional display standards.

Size Limitations and Production Capabilities

Seamless fabric banner production accommodates sizes up to 106 inches wide by 394 inches long without visible joints or seams. These maximum dimensions enable large-format displays for architectural installations and exhibition backdrops. When pole pockets are specified, maximum height reduces to 102 inches to accommodate finishing requirements.

Standard size offerings include popular configurations from 24x36 inches to 10x15 feet, covering most commercial display requirements. Custom sizing enables precise fit for unique applications without material waste or aesthetic compromises. Professional manufacturers maintain extensive size libraries for immediate production scheduling.

Production scheduling typically requires 24-48 hours for standard orders, with rush services available for urgent requirements. Advanced planning ensures adequate production capacity during peak seasons including trade show schedules and promotional campaigns. Furthermore, batch production capabilities provide cost efficiencies for large quantity orders.

Cost Analysis and Investment Considerations

Pricing Factors and Budget Planning

Fabric banner pricing varies significantly based on material weight, size, finishing options, and production volumes. Economy options start around $79.99 for small banners, while premium materials and complex finishing can exceed $300 for large displays. Understanding these cost drivers enables effective budget allocation and specification optimization.

Material costs increase proportionally with fabric weight and quality enhancements. Premium 9oz materials typically cost 40-60% more than economy 3.5oz alternatives, but provide substantially longer service life and enhanced appearance quality. Therefore, cost-per-use calculations often favor premium materials for frequent applications.

Finishing options significantly impact total project costs. Basic hemmed edges add minimal expense, while grommet installation and pole pocket construction increase costs by 15-25%. Complex configurations requiring custom spacing or reinforcement strips command premium pricing but deliver enhanced durability and professional appearance.

Volume discounts provide substantial savings for bulk orders and repeat customers. Quantities exceeding 10 pieces typically qualify for reduced per-unit pricing, while annual contracts can achieve additional cost reductions. Moreover, consolidated ordering minimizes setup charges and production inefficiencies.

Total Cost of Ownership Analysis

Professional fabric banners deliver exceptional return on investment through extended service life and reusability characteristics. Quality materials maintain appearance integrity for 3+ years with proper care, while premium options can exceed 5-year lifespans under optimal conditions. These longevity characteristics often justify higher initial investments.

Maintenance costs remain minimal throughout fabric banner lifespans. Machine washing capabilities eliminate professional cleaning expenses, while steaming equipment removes wrinkles quickly and efficiently. Additionally, modular replacement graphics enable content updates without complete banner replacement, extending utility and value.

Transportation and storage advantages reduce operational expenses significantly. Fabric banners fold compactly without damage, minimizing shipping costs and storage requirements compared to rigid alternatives. Furthermore, lightweight characteristics reduce handling equipment needs and labor requirements during installation procedures.

File Requirements and Design Specifications

Print-Ready Artwork Standards

Professional fabric banner production requires high-resolution artwork files meeting specific technical standards. Image resolution must achieve 150-300 DPI at actual print size to ensure sharp detail reproduction and professional appearance quality. Vector graphics provide unlimited scalability without quality degradation, making them ideal for fabric banner applications.

Color space specifications utilize CMYK profiles optimized for dye sublimation printing processes. RGB files require color space conversion during production, potentially causing color shifts from original designs. Therefore, professional designers create artwork in CMYK mode to ensure accurate color representation throughout the production workflow.

File format compatibility includes Adobe Photoshop (PSD), Adobe Illustrator (AI), and high-quality PDF documents with embedded fonts and linked images. Acceptable formats ensure smooth production workflow while preventing compatibility issues that could delay delivery schedules. Moreover, layered files enable modification flexibility during production approval processes.

Bleed requirements extend artwork 0.125 inches beyond final trim dimensions to accommodate production tolerances. This additional area prevents white edges or incomplete coverage along banner perimeters. Professional templates provide precise guidelines for artwork creation while ensuring optimal production results.

Typography and Readability Guidelines

Font selection significantly impacts readability at various viewing distances and lighting conditions. Sans-serif typefaces generally perform better for large-format displays due to enhanced legibility and cleaner appearance characteristics. Professional designers recommend minimum font sizes of 24 points for body text and 48 points for headlines to ensure adequate readability.

Color contrast ratios must achieve accessibility standards while maintaining brand consistency requirements. High contrast combinations ensure readability under various lighting conditions and viewing angles. Additionally, color psychology considerations influence viewer response and brand perception, making strategic color selection essential for marketing effectiveness.

Text placement requires careful consideration of fabric banner mounting systems and installation environments. Critical information should avoid grommet locations and fold lines to prevent obstruction during display. Furthermore, reading patterns and visual hierarchy guide optimal layout development for maximum communication impact.

Brand Integration and Template Resources

Corporate brand guidelines ensure consistent visual identity across all fabric banner applications. Professional design templates incorporate approved color palettes, typography selections, and logo placement standards. These resources streamline design development while maintaining brand integrity throughout marketing communications.

Industry-specific templates address unique requirements for healthcare, retail, corporate, and event applications. Pre-developed layouts provide starting points for custom designs while incorporating best practices for each market segment. Moreover, template libraries enable rapid design development for time-sensitive projects.

Design consultation services help optimize artwork for fabric banner production while achieving marketing objectives. Professional designers understand material characteristics, printing limitations, and installation requirements affecting final appearance quality. These services ensure successful project outcomes while minimizing revision cycles and production delays.

Industry-Specific Applications and Use Cases

Healthcare and Medical Facility Solutions

Healthcare environments utilize fabric banners for wayfinding, patient education, and promotional communications. Antimicrobial fabric treatments provide enhanced hygiene characteristics appropriate for medical settings. Additionally, machine washable properties enable regular cleaning protocols while maintaining professional appearance standards.

Patient education displays require clear typography and simplified visual hierarchies for optimal comprehension. Healthcare fabric banners often incorporate accessibility considerations including high contrast ratios and multilingual content options. Furthermore, modular design systems enable content updates as medical procedures and protocols evolve.

Regulatory compliance considerations affect content development and material selection for healthcare applications. Professional manufacturers understand medical facility requirements while providing documentation for facility accreditation processes. These specialized services ensure successful healthcare facility implementations.

Retail and Commercial Applications

Retail environments leverage fabric banners for seasonal promotions, product launches, and brand reinforcement throughout store layouts. Point-of-purchase displays utilize fabric banners to highlight special offers while maintaining sophisticated brand presentation. Moreover, changeable graphics enable rapid campaign updates without major display modifications.

Visual merchandising strategies incorporate fabric banners as architectural elements that enhance overall store design. These installations create branded environments while providing functional information display capabilities. Professional fabric banners integrate seamlessly with existing store fixtures and lighting systems.

Shopping center and mall installations require flame-retardant materials meeting building code requirements. Professional manufacturers provide certified materials with appropriate documentation for facility management approval. These specialized options ensure compliance while maintaining aesthetic quality and performance characteristics.

Corporate and Professional Services

Corporate lobbies and reception areas utilize fabric banners for brand reinforcement and visitor orientation. Professional installations create impressive first impressions while communicating company values and capabilities. Additionally, fabric banners provide cost-effective solutions for temporary corporate events and facility modifications.

Conference rooms and meeting spaces benefit from fabric banner installations that enhance presentation environments. Branded backdrops create professional settings for video conferences and client meetings. Furthermore, acoustic properties of fabric materials contribute to improved sound quality in presentation environments.

Executive offices and administrative areas use fabric banners for subtle brand reinforcement and environmental enhancement. Professional installations complement architectural features while avoiding overwhelming decorative elements. These applications require sophisticated material selection and installation techniques for optimal integration.

Environmental Factors and Durability Testing

Indoor vs Outdoor Performance Characteristics

Environmental conditions significantly impact fabric banner performance and longevity expectations. Indoor applications protect banners from UV radiation, precipitation, and temperature extremes, enabling indefinite service life with proper maintenance. Professional indoor installations maintain color vibrancy and structural integrity for 5+ years under controlled conditions.

Outdoor exposure introduces multiple degradation factors including UV radiation, moisture, temperature fluctuations, and wind stress. Dye sublimation graphics gradually fade when exposed to direct sunlight, with noticeable color shifts occurring after 6-12 months of continuous exposure. Therefore, outdoor fabric banner applications require strategic placement and regular replacement scheduling.

Singapore's tropical climate presents unique challenges for outdoor fabric banner installations. High humidity levels can promote mildew growth if banners remain wet for extended periods. Additionally, intense UV radiation accelerates color fading compared to temperate climates, requiring more frequent graphic replacement cycles.

Wind resistance capabilities vary significantly based on fabric weight and installation methods. Heavy-duty 9oz materials withstand moderate wind conditions when properly installed, while lightweight options require protected environments. Professional installations utilize appropriate hardware and mounting techniques to prevent damage during weather events.

UV Resistance and Color Stability Testing

Accelerated weathering tests simulate years of outdoor exposure in controlled laboratory environments. These standardized procedures evaluate color fastness, material degradation, and dimensional stability under extreme conditions. Professional manufacturers utilize these testing protocols to establish realistic performance expectations and warranty parameters.

UV-resistant overcoating treatments extend outdoor performance significantly by filtering harmful radiation before it reaches base graphics. These protective layers maintain color vibrancy 2-3 times longer than untreated alternatives while preserving material flexibility and texture characteristics. Moreover, overcoating applications resist environmental contamination and facilitate cleaning procedures.

Color stability varies significantly between different ink systems and fabric combinations. Premium dye sublimation processes achieve superior fade resistance compared to direct printing methods. Furthermore, darker colors generally maintain stability longer than lighter tones, influencing design strategy for long-term outdoor applications.

Moisture Management and Mildew Prevention

Polyester fabric construction provides inherent moisture resistance while maintaining breathability characteristics. Water-repellent treatments enhance protection against rain penetration while preventing saturation that could lead to mildew development. These treatments maintain fabric flexibility while providing extended outdoor performance capabilities.

Proper drainage considerations prevent water accumulation in pole pockets and folded areas where moisture could remain trapped. Professional installations incorporate drainage strategies while maintaining aesthetic quality and structural integrity. Additionally, ventilation gaps enable air circulation that promotes rapid drying after precipitation events.

Storage protocols require completely dry conditions to prevent mildew growth during extended storage periods. Professional cleaning and drying procedures eliminate moisture and contaminants before storage. Furthermore, breathable storage containers maintain air circulation while protecting banners from dust and environmental contamination.

Storage, Transportation, and Shipping Considerations

Optimal Storage Techniques and Environment Control

Professional storage requires controlled temperature and humidity environments to maintain fabric banner integrity. Ideal conditions include temperatures between 60-75°F and relative humidity levels below 50% to prevent condensation and material degradation. Climate-controlled storage facilities provide optimal protection for valuable banner investments.

Folding techniques minimize space requirements while preventing permanent creasing that could affect display appearance. Professional folding procedures create uniform folds along non-critical areas while avoiding graphic elements and text regions. Additionally, acid-free tissue paper between folds prevents color transfer and surface damage during extended storage.

Rolling storage methods eliminate fold lines entirely but require larger storage spaces and specialized tubes. This approach works best for banners exceeding 8 feet in any dimension where folding could create visible creases. Professional rolling tubes protect banners while enabling efficient organization and retrieval systems.

Shipping and Transportation Best Practices

Compact folding capabilities enable cost-effective shipping through standard courier services rather than specialized freight systems. Fabric banners fold to fractions of their display size, reducing shipping costs by 60-80% compared to rigid alternatives. Furthermore, lightweight characteristics minimize dimensional weight penalties in shipping calculations.

Protective packaging prevents damage during transit while maintaining reasonable shipping costs. Professional packaging systems utilize moisture barriers, cushioning materials, and rigid containers appropriate for banner dimensions and value. These protective measures ensure banners arrive in perfect condition regardless of shipping method or distance.

International shipping considerations include customs documentation, import duties, and delivery restrictions affecting project timelines. Professional shipping services provide complete documentation support while ensuring compliance with destination country requirements. Moreover, tracking systems enable precise delivery coordination for time-sensitive events and installations.

Professional Services and Quality Assurance

Installation Services and Technical Support

Professional installation services ensure optimal display results while preventing damage during setup procedures. Certified technicians understand fabric banner characteristics, hardware requirements, and environmental considerations affecting installation success. These services eliminate installation risks while guaranteeing professional appearance quality.

On-site consultation services evaluate installation environments and recommend optimal mounting solutions. Professional assessments consider structural limitations, environmental factors, and aesthetic requirements while developing comprehensive installation strategies. Furthermore, consultation services prevent costly mistakes and ensure successful project outcomes.

Technical support services provide ongoing assistance throughout fabric banner lifecycles. Professional support teams understand material characteristics, maintenance requirements, and troubleshooting procedures for common issues. Additionally, support services enable users to maximize banner performance and longevity through proper care and handling techniques.

Quality Assurance and Warranty Programs

Comprehensive quality control procedures ensure every fabric banner meets professional standards before shipment. Multi-point inspection processes evaluate color accuracy, material quality, finishing precision, and dimensional accuracy. These quality measures prevent defective products while maintaining consistent production standards.

Manufacturing warranties protect investments against material defects and production errors. Professional manufacturers provide replacement guarantees for materials failing to meet specified performance standards. Furthermore, warranty programs demonstrate manufacturer confidence while providing customer protection for significant investments.

Performance guarantees establish realistic expectations for fabric banner longevity under specified conditions. Professional manufacturers base these guarantees on extensive testing data and field experience. Moreover, performance documentation helps customers plan replacement cycles and budget accordingly for ongoing banner requirements.

PullUpStand.com Professional Display Solutions

Discover our comprehensive Pull-Up Banner Stand Collection featuring high-quality materials and professional finishing options. These portable display solutions deliver exceptional quality for trade shows, corporate events, and retail applications.

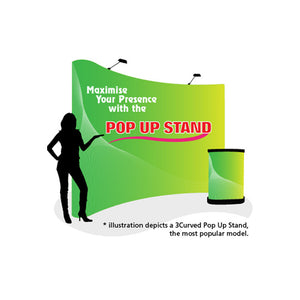

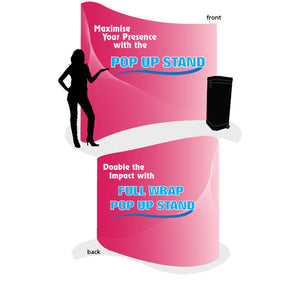

Our Pop-Up Display Systems create impressive backdrop environments for maximum exhibition impact. Professional aluminum frames ensure reliable performance through countless setup and breakdown cycles.

Featured professional display solutions include:

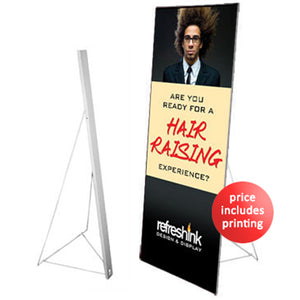

- Deluxe Pull-Up Banner Stand Series - Premium curved base design with tear-proof synthetic materials and professional matte lamination. Starting from S$180

- Professional Pop-Up Display Stand - Complete backdrop solution with aluminum frame and high-resolution graphics. Transform exhibitions instantly. S$2,000

- Giant Flag Pole Banner Stand - Towering 5-meter fabric flag display with water-fillable base for outdoor stability. Maximum visibility impact. S$700

- Premium Pull-Up Banner Stand - Enhanced stability with professional materials and superior build quality for frequent use. Starting from S$110

- Custom Banner Printing Services - Complete printing solutions including fabric banners, vinyl displays, and professional finishing options. Quote on request

Frequently Asked Questions About Fabric Banners

What's the difference between grommets and pole pockets for fabric banners?

Grommets are stainless steel rings embedded along banner edges for rope/hardware attachment, offering versatile mounting options. Pole pockets are sewn sleeves allowing poles to slide through, creating clean installations without visible hardware. Choose grommets for flexibility, pole pockets for professional appearance.

What file format and resolution do I need for fabric banner printing?

Submit artwork in Adobe Photoshop (PSD), Illustrator (AI), or high-quality PDF format at 150-300 DPI actual size. Use CMYK color space for accurate color reproduction. Include 0.125-inch bleed beyond final dimensions. Vector graphics provide unlimited scalability without quality loss.

How much do fabric banners cost compared to vinyl banners?

Fabric banners range from S$79-S$300+ depending on size and material weight. While 20-40% more expensive than vinyl initially, fabric banners offer superior indoor appearance, foldability, and washability. Total cost-of-ownership often favors fabric for repeated use applications.

What's the maximum size for seamless fabric banners?

Professional manufacturers produce seamless fabric banners up to 106 inches wide by 394 inches long without joints. When pole pockets are added, maximum height reduces to 102 inches. Custom sizing accommodates unique requirements without material waste.

How do I prevent wrinkles in fabric banners during storage?

Fold banners along non-critical areas using acid-free tissue paper between folds. Store in cool, dry environments below 50% humidity. For wrinkle removal, use professional steaming equipment or iron on lowest setting with protective cloth. Rolling eliminates folds but requires larger storage space.