What is Spot UV Booklet Printing? Complete Technical Overview

Spot UV booklet printing is a specialized post-printing finishing technique that applies a clear, high-gloss ultraviolet (UV) cured varnish to selective areas of printed booklet covers or interior pages, creating dramatic visual and tactile contrast against matte or soft-touch laminated backgrounds. Unlike full-coverage lamination or flood UV coating that covers the entire printed surface, spot UV targets only specific design elements—logos, typography, imagery, or decorative patterns—identified through a precisely prepared mask file.

The term "spot" refers to the selective application method where UV varnish is applied only to designated spots or areas rather than the complete surface. The "UV" component describes the ultraviolet light curing process that instantly hardens the liquid polymer varnish into a durable, glossy finish within seconds of application.

This premium finishing option elevates standard booklet printing services into high-impact marketing materials that command attention and communicate brand quality through both visual and tactile dimensions.

The Complete Spot UV Printing Process Explained

The spot UV process operates as a multi-stage finishing technique applied after all primary printing operations are complete:

Stage 1: Base Printing & Lamination

All CMYK colors are printed on the booklet cover using offset or digital printing presses. After the ink dries completely, a matte lamination or soft-touch lamination layer is applied to the entire surface. This lamination serves as the essential substrate—spot UV will not work effectively on uncoated paper or glossy lamination because the contrast effect requires a low-sheen matte background.

Stage 2: UV Plate Preparation

A UV plate (similar to a screen printing screen) is manufactured based on the vector artwork in your spot UV mask file. The plate-making process involves coating a fine mesh screen with photosensitive material, exposing it to UV light through photographic film that contains your spot UV design, then washing away uncured areas to create open mesh zones where varnish will flow through.

Stage 3: UV Varnish Application

Clear liquid UV polymer varnish is poured onto the prepared screen and spread across its surface. A squeegee mechanism (either manual or automated) forces the liquid varnish through the open mesh areas of the screen onto specific zones of each booklet cover as sheets pass through the coating machine. Modern digital spot UV equipment like the Duplo DuSense DDC-810 Pro or MGI JETvarnish systems can apply varnish with registration accuracy within ±0.5mm.

Stage 4: Instant UV Curing

Immediately after varnish application, coated sheets pass under high-intensity ultraviolet lamps. The UV light triggers a photochemical polymerization reaction that transforms the liquid varnish into a solid, hardened coating within 1-2 seconds. This instant curing eliminates drying time and allows immediate handling, cutting, folding, and binding operations.

Stage 5: Quality Control & Finishing

Cured sheets are inspected for registration accuracy, coverage uniformity, gloss level consistency, and surface defects. Approved sheets proceed to cutting, scoring (if needed), and binding operations to complete the booklet assembly.

How Spot UV Differs from Other Coating Technologies

Spot UV vs Flood UV Coating:

Flood UV coating applies UV varnish across the entire printed surface without selective masking, providing uniform gloss and protection but no contrast effects. Flood UV serves primarily protective purposes while spot UV serves aesthetic differentiation purposes.

Spot UV vs Aqueous Coating:

Aqueous coating uses water-based varnish that requires air-drying time (15-30 minutes), produces moderate gloss levels, and offers lower durability compared to UV coatings. Spot UV delivers superior gloss intensity, instant curing, and better scratch resistance.

Spot UV vs Traditional Varnish:

Oil-based or spirit-based varnishes require extended drying periods (hours to days), emit volatile organic compounds (VOCs), and provide less durable finishes. UV varnish is more environmentally friendly with minimal VOC emissions and superior performance characteristics.

Spot UV vs Raised/3D Spot UV:

Standard spot UV creates a smooth glossy surface with minimal height variation (5-10 microns). Raised spot UV (also called 3D spot UV or tactile spot UV) builds multiple varnish layers to create substantial dimensional relief of 20-50 microns, producing embossed-like tactile effects without requiring metal dies.

Technical Specifications for Spot UV Booklet Printing

Substrate Requirements

Minimum Paper Weight:

Spot UV requires substantial paper stock to support the coating weight and curing heat:

-

Booklet Covers: Minimum 250gsm art card or board (260-300gsm recommended)

-

Interior Pages: Minimum 128gsm coated paper if applying spot UV to interior pages

-

Maximum Thickness: Up to 450gsm board for specialized equipment

Required Base Coating:

Spot UV must be applied over matte lamination or soft-touch lamination—never on unlaminated paper or glossy lamination. The matte substrate creates essential contrast; glossy lamination renders spot UV effects nearly invisible. Soft-touch lamination (velvet/suede finish) provides the most dramatic tactile contrast with glossy UV.

Design Specifications & Limitations

Minimum Element Sizes:

-

Text: Minimum 8-10pt for regular fonts; avoid serif fonts below 10pt

-

Line Weight: Minimum 1mm (3pt) stroke width for lines and borders

-

Gap Between Elements: Minimum 1.5mm spacing between spot UV areas

-

Registration Tolerance: ±0.5mm to ±1mm depending on equipment

Coverage Limitations:

Industry best practices recommend limiting spot UV coverage to 25-30% of total surface area. Excessive coverage (>50%) eliminates contrast effectiveness and increases production costs. Strategic selective application creates greater visual impact than large-area coverage.

Critical Safety Zones:

-

Edge Clearance: Minimum 3-5mm from all trim edges

-

Fold Line Avoidance: No spot UV within 5mm of any fold, score, or spine areas

-

Binding Edge: Minimum 5-7mm clearance from saddle-stitch or perfect-bind spine

Placing spot UV over fold lines or near edges creates high risk of cracking because the rigid cured polymer cannot flex with paper movement. Understanding these specifications is crucial whether you're producing corporate booklets or marketing brochures.

File Preparation Requirements

Artwork Structure:

Submit spot UV projects as two-layer PDF files:

-

Base Layer: Full-color CMYK artwork with all design elements, 300dpi minimum resolution, 3mm bleed on all sides

-

Spot UV Mask Layer: Separate layer containing only 100% black (K=100, C=0, M=0, Y=0) solid shapes indicating exactly where UV varnish should be applied

Critical Technical Settings:

-

Convert spot UV mask elements to vector format (not raster/bitmap) for crisp edges

-

Assign spot UV layer a designated spot color named "Spot UV" or "UV Varnish"

-

Outline all fonts or embed font files completely

-

Include printer's registration marks for accurate alignment

-

Submit final files as PDF/X-1a or PDF/X-4 for optimal prepress compatibility

For file preparation assistance, refer to PullUpStand.com's templates and specsheets section which provides comprehensive artwork guidelines.

Grayscale Depth Control:

Advanced spot UV equipment allows variable thickness control by using grayscale values in the mask layer. Darker black shades (80-100% black) produce thicker polymer layers with greater dimensional height; lighter grays (40-60%) create subtle coating thickness. This technique enables sophisticated multi-level spot UV effects.

Production Specifications

Minimum Order Quantities (Singapore Market):

Most Singapore commercial printers require 500-1,000 booklets minimum for spot UV finishing. Lower minimums (200-300 pieces) may be available from boutique printers at premium per-unit pricing. The MOQ exists because UV plate preparation incurs fixed setup costs that must be amortized across sufficient quantity.

Standard Production Timeline:

-

File Review & Prepress: 1-2 working days

-

Plate Making: 1 working day

-

Base Printing: 2-3 working days

-

Lamination & Curing: 1 working day

-

Spot UV Application: 1-2 working days

-

Binding & Finishing: 1-2 working days

-

Total Standard Lead Time: 7-10 working days

Express Production: 3-5 working days available with rush surcharges.

Equipment Specifications

Industrial Spot UV Coating Machines:

-

Sheet Size Range: Minimum 60gsm to maximum 450gsm, up to A1 (22" x 32") sheet size

-

Production Speed: 3,000-6,000 sheets per hour depending on coverage area

-

Registration Accuracy: ±0.3mm to ±1mm depending on digital vs analog systems

-

UV Lamp Power: High-intensity mercury vapor or LED UV curing systems

Common Equipment Brands (Singapore Market):

-

Duplo DuSense DDC-810 Pro (digital spot UV coater)

-

MGI JETvarnish 3D (digital variable data spot UV)

-

Konica Minolta AccurioJet KM-1e with UV embellishment unit

-

Screen printing systems with UV curing for traditional spot UV

Comparative Analysis: Spot UV vs Alternative Premium Finishes

Spot UV vs Foil Stamping

Foil Stamping Process:

Hot foil stamping uses metal dies, heat (150-180°C), and pressure to transfer metallic or pigmented foil film onto printed surfaces. The heated die presses the foil against the substrate, bonding a thin layer of reflective material.

Visual & Tactile Differences:

| Characteristic | Spot UV | Foil Stamping |

|---|---|---|

| Appearance | Clear high gloss on matte background | Metallic reflective (gold, silver, colors) |

| Texture | Smooth glossy surface, minimal height | Slight texture with metallic sheen |

| Light Reflection | Directional gloss sheen | Multi-angle metallic reflection |

| Color Options | Transparent clear only | Gold, silver, copper, holographic, colors |

| Durability | Excellent scratch resistance | Good, but can scuff on edges |

| Cost | Moderate investment | Higher investment |

When to Choose Each:

-

Spot UV: When you want sophisticated matte-gloss contrast, need to highlight photography or detailed graphics, prefer understated elegance

-

Foil Stamping: When you want metallic luxury appeal, need maximum attention-grabbing effect, targeting premium/luxury market positioning

Spot UV vs Embossing/Debossing

Embossing/Debossing Process:

Embossing raises areas above the surface while debossing presses areas below the surface using matched male-female metal dies with heat and pressure. The process creates permanent three-dimensional relief in the paper substrate itself.

Comparative Characteristics:

| Factor | Spot UV | Embossing/Debossing |

|---|---|---|

| Dimensional Height | 5-10 microns (standard), 20-50 microns (raised) | 300-800 microns substantial relief |

| Tactile Impact | Moderate smooth/glossy feel | Strong dimensional texture |

| Visual Without Touch | High (gloss contrast visible) | Moderate (depends on lighting) |

| Blind Effect Possible | No (UV is visible gloss) | Yes (debossing with no ink/foil) |

| Setup Cost | Lower plate preparation | Higher metal die costs |

| Production Speed | Faster (6000 sheets/hour) | Slower (1500-3000 sheets/hour) |

| Risk of Cracking | Near folds and edges | Minimal if properly designed |

Combination Techniques:

Registered embossing with spot UV—applying spot UV precisely over embossed areas—creates ultimate premium effects combining dimensional relief with glossy highlights. This combination is commonly used on luxury packaging, premium business cards, and high-end booklet covers.

Spot UV vs Soft Touch Lamination

Soft Touch (Velvet) Lamination:

Soft touch lamination applies a specialty matte film with silky, velvety surface texture that feels similar to suede or peach skin. The tactile sensation provides luxury appeal through touch rather than visual gloss.

Comparison Matrix:

| Aspect | Spot UV Only | Soft Touch Only | Soft Touch + Spot UV |

|---|---|---|---|

| Tactile Sensation | Smooth gloss on matte | Velvety/silky entire surface | Dual texture contrast |

| Visual Impact | High gloss-matte contrast | Subtle low-sheen elegance | Maximum multi-sensory |

| Fingerprint Resistance | Poor (gloss shows prints) | Excellent (hides prints) | Mixed (prints on UV only) |

| Durability | Excellent scratch resistance | Good anti-scuff properties | Excellent combined |

| Investment Level | Moderate premium | Lower premium | Higher premium |

Optimal Application:

Combining soft touch lamination as the base with strategic spot UV accents delivers the strongest multi-sensory brand experience. The velvet background amplifies gloss contrast while the UV areas provide visual focal points. This combination is considered premium finishing for luxury brands, high-end catalogs, and executive booklets.

Strategic Applications: When to Use Spot UV Booklets

1. Corporate Communication Materials

Annual Reports & Financial Publications:

Singapore financial institutions, publicly-listed corporations, and investment firms use spot UV annual reports to communicate stability, professionalism, and attention to detail. Spot UV applied to company logos on covers, executive photography, performance charts, and financial tables creates premium perception that aligns with corporate brand standards. The technique is particularly effective for companies in banking, insurance, wealth management, and professional services sectors where trust and credibility are paramount.

Company Profile Booklets:

B2B companies presenting corporate capabilities to potential clients use spot UV company profiles to differentiate from competitors. Spot UV on cover logos, service category headers, case study imagery, and client testimonial sections guides reader attention to key brand messages. Architecture firms, engineering consultancies, law practices, and management consulting agencies benefit from the sophisticated aesthetic.

2. Premium Product Marketing

Luxury Product Catalogs:

Fashion boutiques, jewelry retailers, premium electronics brands, and lifestyle product marketers use spot UV catalogs to showcase products with enhanced visual appeal. Applying spot UV selectively to product photography creates dimensional depth that makes items appear more desirable and aspirational. The glossy highlights mimic the natural sheen of luxury products (watches, jewelry, cosmetics, leather goods), creating visual consistency between catalog imagery and actual products.

Real Estate Development Brochures:

Singapore property developers marketing high-end residential, commercial, or mixed-use developments rely on spot UV brochures for showflat presentations and property launches. Spot UV on architectural renderings, interior design photography, amenity highlights, and developer logos elevates perceived project quality and justifies premium pricing. Developments in prime districts (Districts 9, 10, 11, Sentosa) particularly benefit from luxury finishing that matches property positioning.

3. Hospitality & F&B Applications

Hotel Service Directories:

Four- and five-star hotels, boutique properties, and luxury resorts use spot UV service directories and in-room collateral to reinforce premium positioning. Spot UV on hotel logos, signature restaurant names, spa service photography, and concierge contact information creates memorable guest touchpoints.

Fine Dining Menus:

Premium restaurants, celebrity chef establishments, and luxury F&B venues use spot UV menu booklets to justify high price points and create upscale dining atmosphere. Spot UV applied to restaurant logos, chef signatures, signature dish names, or wine list section headers communicates quality and craftsmanship before food arrives. The tactile experience during menu browsing sets psychological expectations for the dining experience quality.

4. Professional Services Marketing

Legal & Consulting Proposals:

Law firms, management consultancies, and professional service providers competing for high-value contracts use spot UV presentation booklets to communicate premium service quality. In Singapore's competitive professional services market where multiple firms pitch for the same engagements, spot UV finishing creates differentiation through tangible quality signals.

Medical & Healthcare Communications:

Aesthetic clinics, specialty medical practices, dental clinics, and healthcare providers targeting private-pay patients use spot UV booklets for treatment menus, before-after portfolios, and service presentations. Spot UV on doctor credentials, treatment result photography, technology highlights, and facility imagery builds trust and justifies premium medical service pricing.

5. Event & Exhibition Materials

Trade Show Literature:

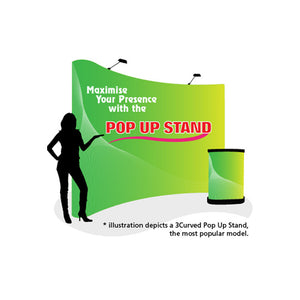

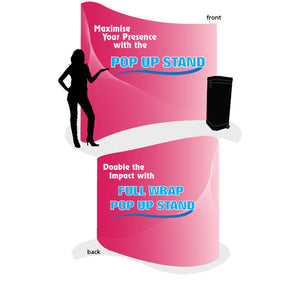

Companies exhibiting at Singapore Expo, Marina Bay Sands Expo, or Suntec Singapore Convention Centre use spot UV booklets to compete for attention among dozens of exhibitors. The glossy highlights catch overhead lighting differently than standard printed materials, improving booklet visibility on crowded display tables. Exhibition attendees collecting materials from multiple booths are more likely to retain and review spot UV booklets post-event.

For comprehensive exhibition display strategies, explore PullUpStand.com's guide on exhibition booth design to maximize your trade show ROI.

Conference Programs & Event Guides:

Professional conferences, corporate events, and premium seminars use spot UV program booklets to reflect event quality and sponsor brand standards. Spot UV on event logos, keynote speaker photography, sponsor logos, and schedule headers enhances perceived event professionalism.

6. Education & Training

University Prospectuses:

Universities, business schools, and executive education programs use spot UV prospectuses to attract qualified applicants. Spot UV on university crests, program titles, campus photography, faculty profiles, and accreditation logos communicates institutional quality and academic excellence.

Professional Training Materials:

Corporate training providers, professional development organizations, and certification bodies use spot UV training manuals and workbooks to create premium learning materials that participants value and retain. The elevated finishing reinforces the investment value of the training program.

Advantages & Limitations of Spot UV Booklet Printing

Primary Advantages

1. Enhanced Visual Hierarchy

Spot UV creates clear focal point prioritization by making selected elements literally shine against matte backgrounds. Eye-tracking research demonstrates that spot UV elements receive 40-60% more visual attention than non-coated areas, dramatically improving message retention and call-to-action visibility.

2. Multi-Sensory Brand Engagement

The tactile dimension engages recipients through touch interaction in addition to visual perception. When potential customers physically feel the contrast between smooth glossy UV and soft matte lamination, they engage with your brand through multiple sensory channels simultaneously—a powerful differentiator that digital marketing cannot replicate.

3. Premium Quality Perception

Spot UV immediately signals brand investment and quality consciousness to recipients. The finishing technique costs more than standard printing, and recipients unconsciously associate this visible investment with overall brand quality—a psychological halo effect that benefits product perception and pricing justification.

4. Superior Durability & Protection

Cured UV polymer provides additional surface protection beyond standard lamination. The coating resists scratches, scuffing, moisture, and fingerprints in coated areas. For booklets requiring extended use or frequent handling—product catalogs, training manuals, hotel directories—this durability extends material lifespan and maintains professional appearance.

5. Instant Production Readiness

UV curing happens within 1-2 seconds of application, eliminating drying time and allowing immediate post-processing. Unlike aqueous coatings or traditional varnishes requiring hours of drying, UV-coated booklets can be cut, scored, folded, and bound immediately after coating, reducing overall production time.

6. Environmentally Friendly

UV curing technology produces minimal volatile organic compounds (VOCs) compared to solvent-based coatings. The instant curing process eliminates air-drying emissions, and modern LED UV curing systems further reduce energy consumption. While the cured plastic coating affects recyclability, the reduced emissions during production offer environmental advantages.

7. Creative Versatility

Spot UV works across diverse design styles and industries—from minimalist corporate aesthetics to bold creative expressions. The technique adapts to conservative financial services branding, luxury fashion catalogs, modern tech company materials, and hospitality marketing. Design flexibility allows both subtle sophistication and dramatic visual impact depending on coverage strategy.

Primary Limitations

1. Increased Production Cost

Spot UV adds cost premium over standard booklet printing. This includes UV plate/screen preparation, specialized varnish materials, additional machine time, and quality control requirements. For budget-conscious projects or mass-distribution materials, the cost may not justify the benefits.

2. Cracking Risk on Folds & Edges

The rigid cured polymer cannot flex like paper substrate, creating crack risks when applied near fold lines, scores, spine areas, or trim edges. If booklet covers are heavily handled or binding areas stressed, UV coating can crack and peel. Proper design with 5mm safety zones from all mechanical stress points is essential.

3. Design Complexity & File Requirements

Spot UV requires precise file preparation with separate mask layers, vector artwork, spot color specifications, and proper registration marks. Designers unfamiliar with spot UV technical requirements may submit incorrect files causing production delays. Small text, fine lines, and intricate details often don't reproduce well due to ±0.5mm registration tolerances.

4. Minimum Order Quantity Constraints

Most Singapore printers require 500-1,000 booklet minimums for spot UV, making it unsuitable for small-quantity projects. The MOQ exists because plate preparation and setup costs must be amortized across sufficient volume. Companies needing 50-200 booklets face either prohibitive per-unit costs or must choose alternative finishing.

5. Fingerprint & Smudge Visibility

High-gloss UV surfaces show fingerprints more readily than matte finishes. For booklets subject to frequent handling, the glossy areas may appear smudged or dirty after multiple touches. This limitation is particularly relevant for retail catalogs, training manuals, and restaurant menus with extended use cycles.

6. Limited Substrate Compatibility

Spot UV requires specific base conditions—matte or soft-touch laminated surfaces on minimum 250gsm cardstock. The technique doesn't work on uncoated papers (varnish absorbs unevenly), glossy lamination (no contrast), or lightweight stocks below 200gsm (curl and warping issues). These substrate limitations restrict application flexibility.

7. Recyclability Considerations

The cured plastic polymer coating complicates paper recycling processes. While the paper substrate remains recyclable, the UV coating must be separated during pulping, potentially reducing recycling efficiency. Environmentally-conscious organizations prioritizing circular economy principles may view this as a disadvantage despite the reduced VOC emissions during production.

8. Increased Production Time

Adding spot UV extends total production timeline by 2-3 days compared to standard booklet printing. The additional time comes from plate preparation, coating application, quality control, and coordination between printing and finishing departments. Rush projects with tight deadlines may not accommodate spot UV production requirements.

Cost & Pricing Information

Get Your Custom Spot UV Booklet Quote

Spot UV booklet printing pricing varies based on several factors including quantity, booklet size, page count, paper weight, coverage area, and production timeline. Because every project has unique requirements, we provide customized quotations tailored to your specific needs rather than fixed pricing.

Pricing factors we consider:

-

Quantity: Higher volumes provide better per-unit value

-

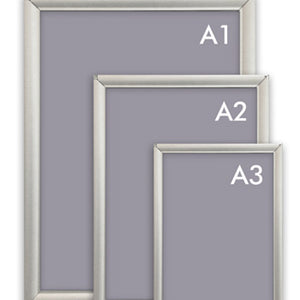

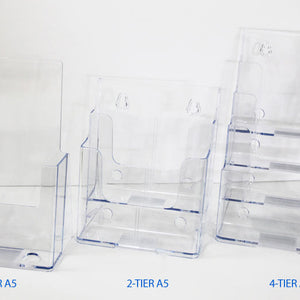

Size & Page Count: A4, A5, A6 booklets with varying page numbers

-

Paper Stock: Premium quality art card and interior paper options

-

Spot UV Coverage: Percentage of cover area requiring UV coating

-

Turnaround Time: Standard or express production schedules

-

Additional Finishes: Soft-touch lamination, embossing, foil stamping combinations

Request Your Free Quote Now

Getting an accurate quotation is quick and easy:

Simply provide:

-

Desired booklet size (A4/A5/A6)

-

Number of pages

-

Quantity needed

-

Any specific requirements or deadline

Our printing specialists will respond within hours with a detailed quotation and professional recommendations for your spot UV booklet project.

Singapore Spot UV Printing Services

PullUpStand.com: Premium Spot UV Booklet Solutions

PullUpStand.com specializes in premium booklet printing services including spot UV finishing for Singapore businesses seeking superior quality marketing materials. With 18+ years of experience serving over 10,000 satisfied clients and a 98% satisfaction rate, PullUpStand.com delivers spot UV booklets that elevate brand presentation.

Why Choose PullUpStand.com:

Advanced UV Coating Technology: State-of-the-art UV coating equipment ensures precise application, consistent gloss levels, and perfect registration between base artwork and UV layers.

Professional Design Support: Experienced graphic designers provide spot UV placement recommendations optimized for maximum visual impact and production feasibility. View the design gallery for inspiration.

Quality Materials: Premium paper stocks from trusted suppliers, professional-grade UV varnish, and high-quality lamination films ensure superior finished products.

Transparent Pricing: Factory-direct pricing without middleman markup delivers excellent value for premium finishing services. No hidden fees—every cost component clearly explained.

Fast Turnaround: Efficient production workflows and dedicated customer service teams ensure your booklets are delivered on schedule without compromising quality.

Complete Printing Solutions: Beyond spot UV booklets, PullUpStand.com offers comprehensive printing services including:

This makes PullUpStand.com your one-stop solution for all marketing collateral needs.

Frequently Asked Questions (FAQs)

Q: Can I apply spot UV on uncoated paper or cardstock?

No, spot UV requires matte or soft-touch laminated substrates as the base coating. Applying UV varnish directly to uncoated paper causes the liquid to absorb unevenly into paper fibers, resulting in dull, blotchy appearance rather than high-gloss finish. The laminated surface provides the necessary non-porous substrate for proper UV coating.

Q: Why doesn't spot UV work on glossy lamination?

Spot UV creates visual impact through contrast between glossy and matte surfaces. When applied over glossy lamination, both the UV-coated and non-coated areas appear glossy, eliminating the contrast effect that makes spot UV distinctive. The technique becomes nearly invisible and wastes production costs.

Q: What is the actual thickness of spot UV coating?

Standard spot UV coating thickness ranges 5-15 microns (0.005-0.015mm). Raised spot UV or 3D spot UV builds up to 20-50 microns through multiple varnish layers. For comparison, standard paper is 100-300 microns thick, so spot UV adds minimal but tactilely perceptible height.

Q: Can spot UV crack or peel off over time?

Yes, if improperly applied or placed in mechanically stressed areas. The cured polymer coating is rigid and cannot flex like paper substrate. Cracking occurs most commonly when:

-

UV is placed within 5mm of fold lines or scores

-

Applied near spine areas subject to bending stress

-

Excessive coverage (>50%) causes rigidity across entire surface

-

Inferior varnish or insufficient curing

Proper design following safety zone guidelines prevents cracking in normal use.

Q: Is spot UV environmentally friendly?

Partially. UV coating produces minimal VOC emissions during production compared to solvent-based coatings. LED UV curing systems further reduce energy consumption. However, the cured plastic polymer coating complicates recycling—the coating must be separated from paper fibers during pulping. Overall environmental impact depends on whether you prioritize production emissions (UV is better) or end-of-life recyclability (standard printing is better).

Q: What's the difference between spot UV and spot varnish?

Spot UV specifically refers to ultraviolet-cured polymer varnish applied selectively and instantly hardened under UV lamps. Spot varnish is a broader term that can include water-based or oil-based varnishes applied to selective areas but cured through air-drying rather than UV light. Spot UV provides higher gloss intensity, faster curing, and better durability than traditional spot varnish.

Q: Can I combine spot UV with other finishing techniques?

Yes, multiple premium finishing techniques can be layered:

-

Embossing + Spot UV (Registered): Emboss the design first, then apply spot UV precisely over raised areas for maximum dimensional effect

-

Foil Stamping + Spot UV: Apply metallic foil to some elements, spot UV to others

-

Soft Touch Lamination + Spot UV: The most common premium combination—velvet lamination base with glossy UV accents

Combination techniques significantly increase production costs and complexity but deliver ultimate luxury finishing.

Q: How much does spot UV booklet printing cost?

Pricing varies based on quantity, size, page count, coverage area, and timeline. For accurate quotation tailored to your specific project requirements, contact us via WhatsApp and our specialists will provide detailed pricing within hours.

Q: What file format should I submit for spot UV booklets?

Submit PDF/X-1a or PDF/X-4 format with separate spot UV mask layer. The PDF should contain:

-

Base CMYK artwork at 300dpi minimum resolution

-

Separate spot UV layer with 100% black (K=100, C=0, M=0, Y=0) vector shapes

-

3mm bleed on all sides

-

All fonts outlined or embedded

-

Registration marks for alignment

Consult PullUpStand.com's templates and specsheets for detailed file preparation guidelines.

Expert Recommendations: Maximizing Spot UV Effectiveness

Design Best Practices

1. Leverage Matte-Gloss Psychology

Human perception associates matte surfaces with sophistication and gloss with emphasis and energy. Design spot UV placement to reinforce this psychology—use matte backgrounds for restrained professionalism while glossy UV accents draw attention to key brand elements that deserve excitement (logos, calls-to-action, hero imagery).

2. Apply the 25% Coverage Rule

Limit spot UV to maximum 25-30% of surface area for optimal visual impact. When coverage exceeds 50%, the contrast effect diminishes and production costs escalate. Strategic selective application creates greater memorability than large-area coverage.

3. Use Bold Design Elements

Spot UV works best on solid shapes, bold typography, and substantial graphics. Avoid applying to:

-

Serif fonts below 10pt or sans-serif below 8pt

-

Lines thinner than 1mm (3pt)

-

Intricate patterns with fine details

-

Large solid areas (creates fingerprint visibility issues)

4. Create Strategic Visual Hierarchy

Use spot UV to establish clear information prioritization:

-

Primary level: Company logo with spot UV

-

Secondary level: Key headlines or value propositions with spot UV

-

Tertiary level: Supporting text and body copy without UV

This hierarchy guides reader attention through your message systematically.

5. Consider Lighting Conditions

Spot UV effects appear most dramatic under directional lighting (spotlights, desk lamps, retail lighting). In diffuse lighting environments (outdoor daylight, fluorescent office lighting), the gloss contrast is less pronounced. Design for your booklet's expected viewing conditions—exhibition materials need more aggressive spot UV coverage than corporate boardroom presentations.

Industry-Specific Recommendations

Financial Services & Banking:

Apply spot UV to company logos, performance charts, and executive imagery while maintaining conservative overall aesthetic through substantial matte areas. Avoid trendy design approaches—financial institutions require timeless sophistication.

Real Estate & Property:

Use spot UV on architectural photography, floor plan highlights, and developer logos to make properties appear more desirable. Consider soft-touch lamination base for maximum tactile luxury that mirrors high-end property finishes.

Hospitality & F&B:

Apply spot UV to signature elements—hotel logos, restaurant names, chef signatures, or award badges. For menu booklets, limit UV to cover and section dividers rather than every page (reduces fingerprint visibility).

Professional Services:

Emphasize credentials and expertise indicators with spot UV—accreditation logos, case study headers, service category titles. Maintain substantial white space and matte areas to communicate clarity and transparency.

Retail & Product Marketing:

Focus spot UV on product photography and packaging imagery to create dimensional appeal. Consider raised spot UV for products where tactile experience matters (cosmetics, textiles, food).

Production Management Tips

1. Order Physical Samples First

Before committing to large quantities, request sample booklets to evaluate gloss intensity, registration accuracy, and overall quality. Spot UV appearance varies significantly between printers depending on equipment and materials.

2. Request Press Checks for Critical Projects

For high-stakes booklets (investor presentations, major trade shows, new brand launches), request on-press inspection during spot UV application to verify registration and coverage before full production run.

3. Plan Production Timeline Conservatively

Always allocate minimum 10-14 days for spot UV booklet projects including file preparation, proofing, production, and delivery. Last-minute rush orders compromise quality and may incur premium charges.

4. Maintain Digital Artwork Archives

Save complete spot UV file packages (base artwork + mask layer + specifications) for future reprints. Having print-ready files reduces reorder turnaround and eliminates redesign costs.

Conclusion: Strategic Value of Spot UV Booklet Printing

Spot UV booklet printing represents a strategic investment in brand perception and marketing effectiveness rather than a mere aesthetic upgrade. The technique delivers measurable benefits—improved visual attention (40-60% increase on UV elements), enhanced brand recall through multi-sensory engagement, competitive differentiation in crowded markets, and premium quality perception that justifies higher pricing.

For Singapore businesses operating in competitive sectors where first impressions matter—financial services, real estate, professional services, luxury retail, hospitality—spot UV booklets provide tangible competitive advantages. The investment makes particular sense for high-value sales cycles, premium brand positioning, trade show marketing, and customer acquisition scenarios where improved conversion rates deliver substantial ROI.

However, spot UV is not universally appropriate. Mass-distribution materials, budget-conscious projects, small quantity needs below 500 units, or applications where booklets face heavy mechanical stress (frequent folding) may benefit more from alternative finishing options. Understanding these strategic considerations—rather than applying spot UV indiscriminately—separates effective marketing investments from wasteful expenditures.

Get Started with Premium Spot UV Booklet Printing

Transform your corporate booklets, product catalogs, and marketing brochures into premium brand assets that command attention and communicate quality. PullUpStand.com's spot UV booklet printing services deliver the sophisticated finishing that Singapore businesses need to stand out in competitive markets.

Contact PullUpStand.com Today:

📱 WhatsApp (Fastest Response):

Share on WhatsApp

📞 Phone: +65 6745 1153 (Mon-Fri 9am-6pm)

💻 Website: pullupstand.com

📧 Email: info@pullupstand.com

📍 Visit Our Showroom:

61 Ubi Rd 1, #03-16 Oxley Bizhub, Singapore 408727

(Please make appointment before visiting)